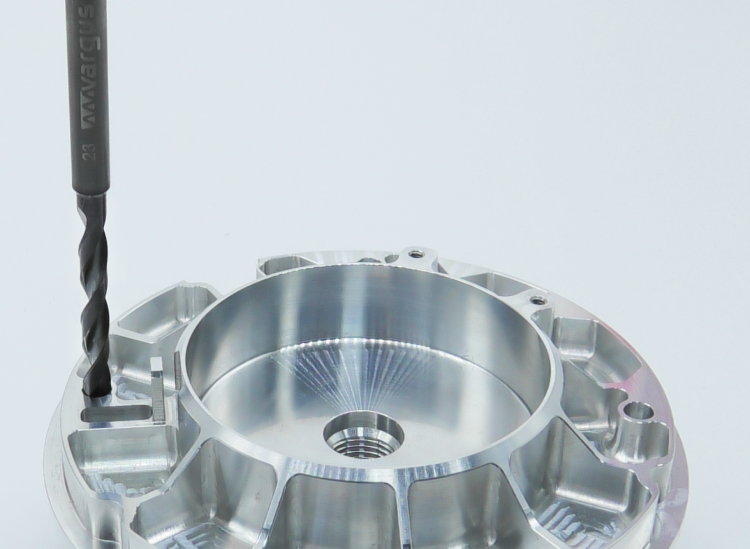

V-Drill: Solid Carbide Drilling Tools

The newest line of solid carbide drilling tools now includes over 150 additional items to cover a complete range of applications with dedicated tools for specific materials such as Stainless Steel, Titanium Alloys, Alloy Steel, and Carbon Steel.

Offering optimized drill design, enhanced edge preparation surface quality, and cutting-edge NANO substrate and coating technologies, the results are tools that deliver exceptional performance, longevity and precision for application-specific solutions.

Explore the entire V-Drill range

Features & Benefits

- Solid Carbide Drills Diameter Range: 1.0 mm (.039”) to 20.0 mm (.783”)

- Pre-Drilling and Pilot Holes for Thread Mills - 3XD-C and 5XD-C: up to 21.0 mm (.826”)

- Multiple Length-to-Diameter Configurations: 3XD, 5XD, 8XD, 12XD with and without Coolant thru for machining Stainless Steel, Steel, and Titanium

- Center (NC) Drills: 90° and 120°

- Optimized Design: Engineered for maximum stability and efficiency, Vargus drilling tools reduce vibration and enhance cutting accuracy.

- Unique Tool Diameter: For pre-drilling operations, perfectly matched with thread milling cutters and taps to create a seamless machining process for M-Coarse, UNF, UNC, NPT and BSP standards.

- Superior Edge Preparation: Each drill edge is prepared to the highest standards, minimizing wear, ensuring repeatability, and extending tool life.

- Advanced Carbide Grade: Our drilling tools utilize the latest NANO substrate and coating technologies, providing superior hardness and heat resistance for consistent performance in the toughest materials.

- Versatility: V-Drill tools are designed to handle a wide range of applications with ease and reliability, whether working with Stainless Steel, Titanium Alloys, Alloy Steel, or Carbon Steel.

See it in Action: