VARDEX - Thread Milling

The VARDEX Thread Milling Line offers an all-encompassing range of solutions.

VARGUS offers an advanced Thread Milling Line featuring innovative cutting tools designed for precise thread mills across various industrial applications.

The VARDEX THREAD MILLING line provides a wide range of applications and solutions in multi-tooth, single-tooth for deep holes, and solid carbide tools.

The Thread Milling Advantages video series provides a detailed overview of the key benefits of the thread milling process and includes system advantages, useful tips, and how-to guides.

Watch the most important advantages of the thread milling system to get a full overview in a series of engaging animated movies.

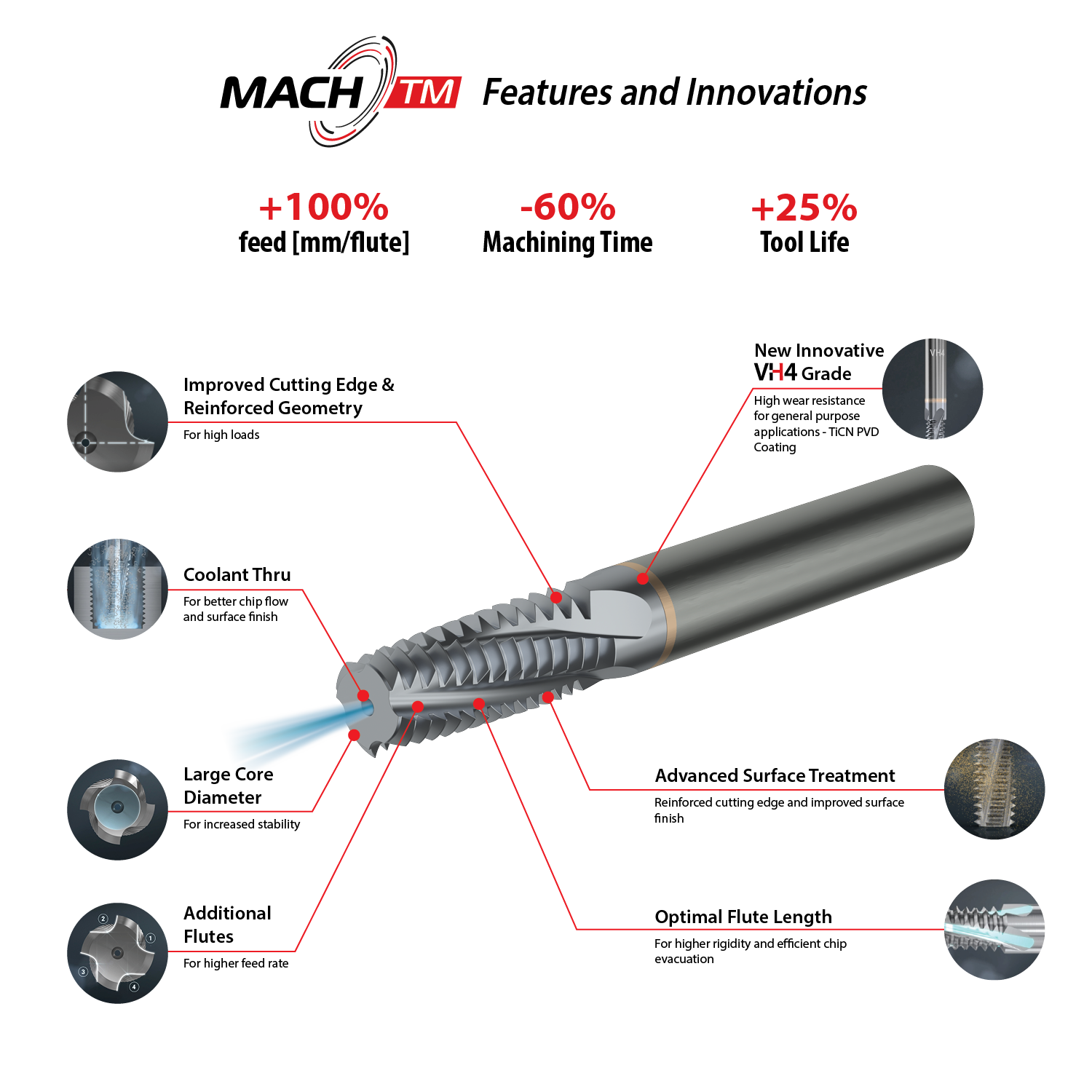

See the latest innovations in Thread Milling:

The Thread Milling Line features the following product families:

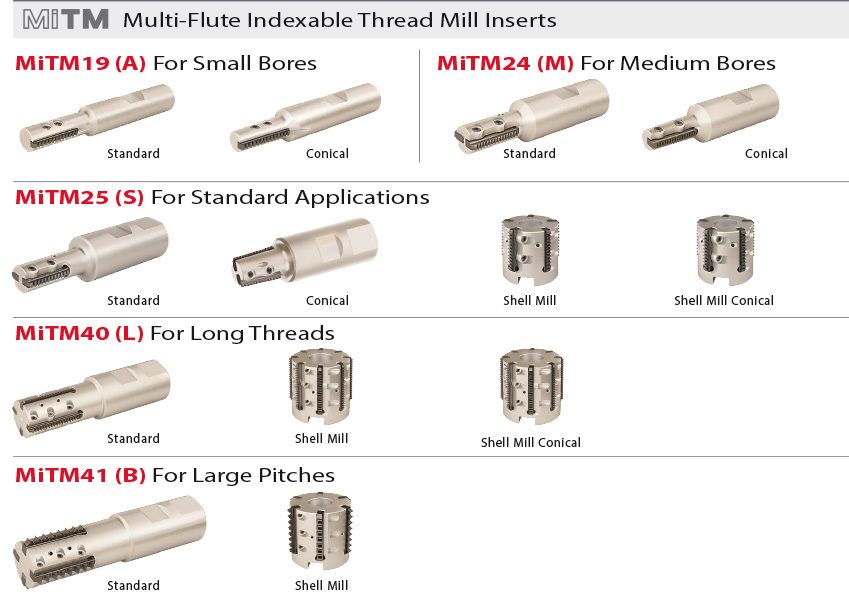

MiTM - Multi-Flute Indexable Thread Milling

An innovative system for fast machining and reducing cycle times when machining threads with long inserts.

MiTM holders are nickel coated, providing anti-rust protection.

MiTM tools are offered in Standard, Conical, Shell Mill & Shell Mill Conical.

The VARDEX Multi-flute Indexable Thread Milling (MiTM) system for fast machining, reduces cycle times when machining threads with long inserts. New nickel coating for all MiTM toolholders provides better anti-rust protection.

See it in Action:

TMSD - Thread Milling for Deep Holes

A multi-flute, highly productive and economical solution for milling threads in deep holes.

The TMSD line also offers full profile inserts in ISO Metric, American UN, NPT, API Round & American Buttress.

TMSD Line System Advantages:

Smooth Cut - Reduced load on cutting edges due to single point insert design

Wide Range of Profiles - Full profile: ISO, UN, NPT, API RD & ABUT. Partial profile: 60°, 55°, Semi Partial profile for: TR, ACME, Stub ACME

Cost Effective - Up to 3 cutting edges per insert. Very high feed per tooth

Fast Machining - Multi-flute, up to 7 cutting edges (inserts)

Long Overhang - Up to 144mm (200mm in Shell Mill)

Coolant Thru - For improved chip evacuation and cooling at the cutting corner

Vertical Inserts - Reinforced Cutting Corner Support

Smaller Tool Cutting Diameter with 3 Flutes - As small as 10.5mm

Conical Thread Preparation - Capabilities to machine conical threads from a cylindrical pre-drilled hole

See it in Action:

TM Standard

VARGUS is known as the first producer of Thread Milling tools, using the TM Standard.

The TM Standard is the most common industry method based on indexable multitooth inserts. All the teeth are machined simultaneously so every tool creates one pitch.

See it in Action:

TM Solid - Solid Carbide Thread Milling Tools

A complete range of miniature and long solid carbide tools, available with and without coolant.

The TM Solid line features a wide range of solid carbide thread milling tools for general purposes as well as specific wide-ranging industries from automotive and taps, to medical and dental.

The advantages of using the VARDEX TM Solid line are:

- Small thread due to small cutting diameter

- Multi flutes for extremely fast machining

- High rigidity

- Unique design for machining hard materials (up to 63 HRc)

- High accuracy

- Designed to fit specific applications

- Cylindrical shank - hydraulic and shrink fit clamping

- Minimal run-out

See it in Action:

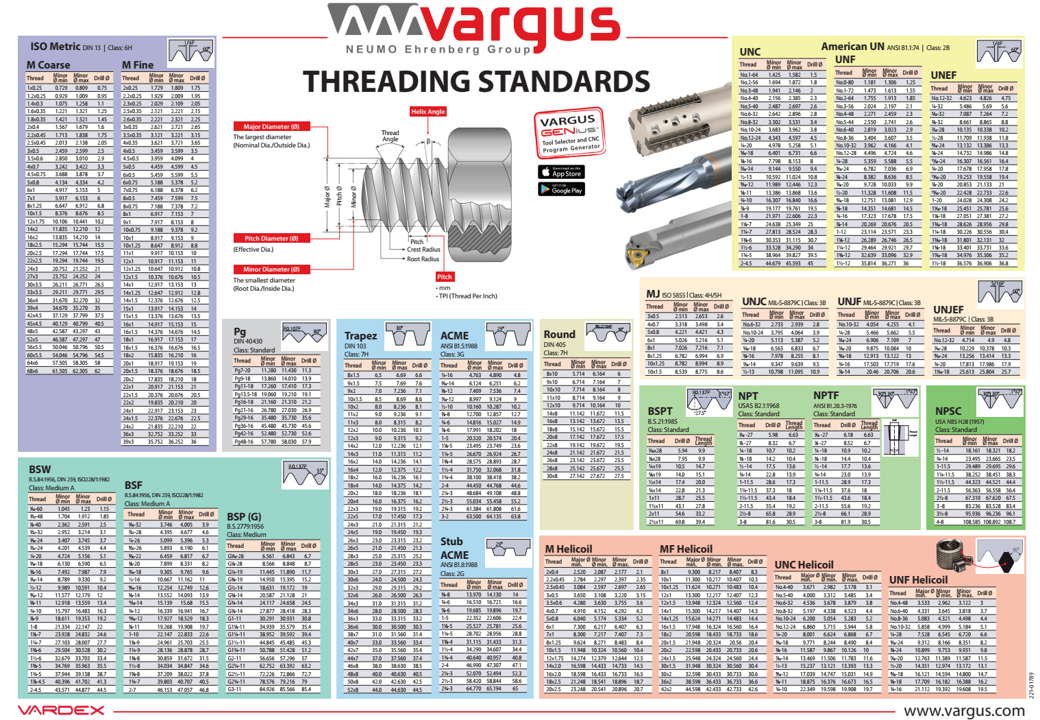

VARGUS Threading Standards Poster

Features:

- Convenient & valuable tool for designers and machine operators

- Covering the most popular Thread Standards in the market

- Each standard/application includes the Minor Diameter and Tolerance, plus the recommended drill sizes

- Very user-friendly: Color-coded standards

VARGUS CASE STUDIES

Discover how VARGUS solutions deliver real results.

Explore our Thread Milling Case Studies to see proven successes, innovative applications, and measurable productivity gains from customers around the world.

Learn how our tools make a difference - in every industry and every challenge.