LMT Tools

LMT Tools' global experts combine the know-how of the LMT Belin, LMT Fette, LMT Kieninger and LMT Onsrud brands. LMT Tools is also part of the LMT Group, a family-run holding company.

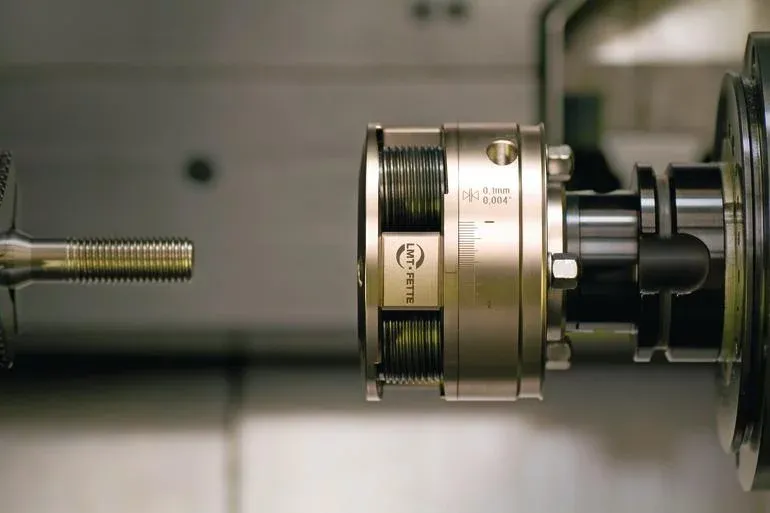

LMT Fette

Schwarzenbek,Germany

LMT Fette is one of the global leaders in the production of gear hobs for cogs and rolling heads for thread production. The company was founded in 1908.

Expertise

Since its founding, the company has been a driver of the ongoing development of gear production.

2010: Presentation of the first nanostructured multilayer coating for gear hobs

Innovative solutions such as heat-resistant coatings which protect tools against high temperatures during cutting.

Latest gear hob development: “SpeedCore” with an intermetallic milling core for increased cutting speed.

LMT Kieninger

Lahr, Germany

Within LMT Tools, LMT Kieninger is the specialist for especially complex cutting operations. They develop and produce customized tool systems and tools for die and mould making.

Expertise

Solutions in the areas of lightweight engineering, complex geometries, high surface grades and demanding materials.

Customized tools. Example: Line boring bars with integrated slide tools for machining large diesel motors.

Monobloc tools (customization of the shape of the tool holder and the cutting material to the machine and workpiece).

Combination of milling holders and cutting materials in die and mould making.

LMT Onsrud

Waukegan, USA

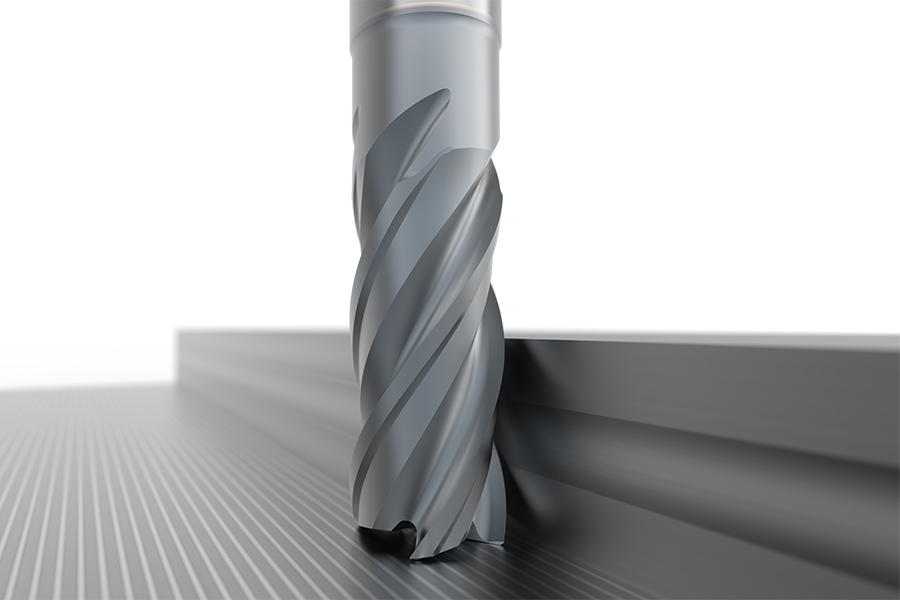

LMT Onsrud specializes in carbide milling cutters, focused in particular on the high-speed machining of aluminum, plastic, and composite materials.

Expertise

Development and production of tools for machining composite materials.

Tools for the machine processing of fiber composites and honeycomb materials.

Innovative tools for high-speed milling.

High-quality tools for additional uncommon materials (for aircraft construction or medical technologies, for example).